I morsetti in plastica per tubi sono un nuovo tipo di fissaggio della struttura con rete resistente che viene combinato con varie caratteristiche di plastica e ben progettato con una struttura precisa del tipo di dente per convertire la forza di effetto mediante regolazione dell'aspetto struttura. La clip per tubo in plastica è un accessorio di nuovo tipo usato comune per il collegamento, il fissaggio e la sigillatura dei tubi, che può sostituire i dispositivi di fissaggio tradizionali come viti e dadi, fascette stringitubo in metallo e corda ecc., E anche con i vantaggi di un facile fissaggio, forte forza, buona tenuta, comodo smontaggio, riciclo e prestazioni ad alto costo.

RunzeFornisce fascette stringitubo in plastica di qualità in vendita, i robusti fascette stringitubo OEM sono completamente supportati.

Model No. (New) | Material | Color | Adapted Diameter (mm) | Product Width (mm) |

1000000001 | POM | White | 3.8-4.3 | 22 |

1000000004 | 4.3-4.8 | 22 | ||

1000000003 | 4.9-5.4 | 22 | ||

1000000024 | 5.5-6.0 | 22 | ||

1000000010 | 6.0-6.5 | 22 | ||

1000000002 | 6.5-7.0 | 23 | ||

1000000013 | 7.0-7.5 | 24 | ||

1000000005 | 7.5-8.0 | 24 | ||

1000000006 | 8.0-8.5 | 26 | ||

1000000018 | 8.6-9.1 | 26 | ||

1000000012 | 9.1-9.6 | 26 | ||

1000000007 | 9.6-10.2 | 25 | ||

1000000008 | 10.2-10.7 | 26 | ||

1000000015 | 10.7-11.2 | 25 | ||

1000000016 | 11.1-11.6 | 25 | ||

1000000009 | 11.6-12.1 | 24 | ||

1000000011 | 12.0-12.5 | 26 | ||

1000000017 | 12.6-13.1 | 28 | ||

1000000023 | 12.3-14.0 | 25 | ||

1000000014 | 13.1-13.6 | 33 | ||

1000000022 | 13.7-14.2 | 28 | ||

1000000025 | 14.2-14.7 | 27 | ||

1000000019 | 14.7-15.2 | 27 | ||

1000000020 | 15.2-15.7 | 27 | ||

1000000053 | 15.2-17 | 32 | ||

1000000055 | 21.5-23.5 | 40 | ||

| 1000000021 | 24.3-26.1 | 48 | ||

| 1000000026 | 35.5-37.5 | 51 |

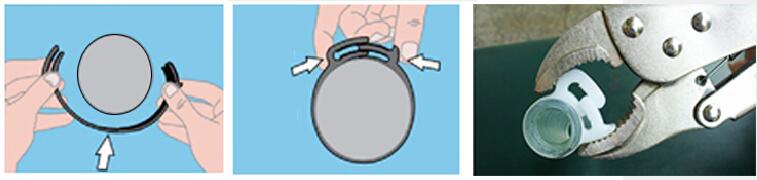

a. Connecting your tube fully into a connector

b. Use vernier calipers to measure the total diameter where you want to fix after tubing connected with connector (see above figure)

c. Choose a suitable model according to above-adapted Diameter listings

d. Slip the hose clamp until reaching the connector, then close the gear until it is tightly fastened

Clamp the outermost tooth with a wire-cutter (please don't clamp left and right tooth together), move flatly and gently as the tooth slot, fleetly twist it with small angle(upper and nether tooth misplaced), then it will be loosened, Please note keep small angle when twisting to ensure the tooth non-deformed when misplaced it is reusable.

Solutions for Common Problems

1. Checking the fastening effect

Rotate the hose clamp manually to ensure it is tightly fastened with no blind side, good sealing and a smooth fastening surface.

2. Leakage and shed after pressured

a. Leakage after pressed includes many caused such as hose clamp with insufficient force, the diameter of the tube is far more than the outer diameter of the connector, a tube with insufficient flexibility, etc.

b. Shed after pressured includes two causes: one is surpassing limit pressure of hose clamp with inner tooth prop up the outer tooth, multi-tooth lose common mesh (only rely on the main tooth); another is the friction force between tube shed off (head part is still fastened). The solution is to choose the right specification or simultaneously use two pieces of hose clamps (head part should be placed at two places, or it will be hard to disassemble)